Today, our focus will be on how to optimize the torque converter function and overall performance of a drag racing vehicle by correctly gearing the combination. It is important to note that this discussion is centered around maximizing performance in a drag racing setting, as street-driven combinations and budget builds often require compromises in gearing for drivability and cost. However, the principles we will share here can still be applied to these scenarios in order to achieve the best drag strip performance.

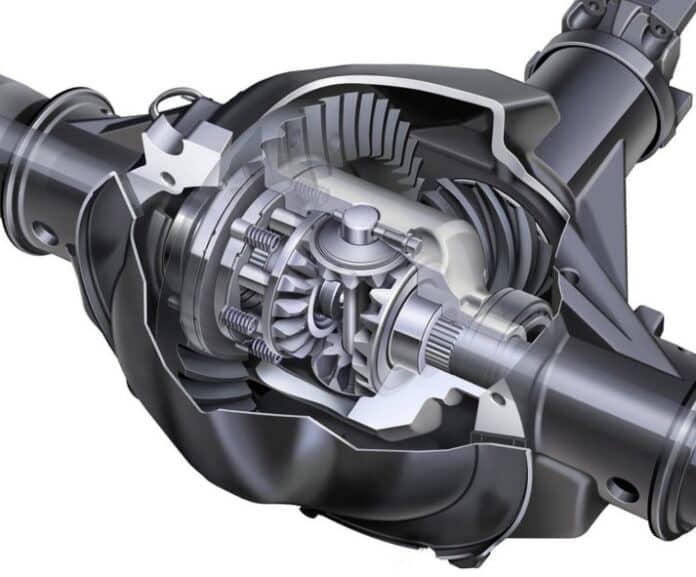

To correctly gear a vehicle for drag racing, the final drive ratio (axle ratio) must be selected first, before choosing a torque converter, transmission, or transmission ratios. This means considering the desired finish line speed and engine RPM, as well as the torque converter slip percentage at the finish line, drive tire height, and transmission ratio. These parameters can be plugged into an equation to determine the mathematically ideal final drive ratio, which can then be used to select a ring and pinion that closely matches this ratio. There are also online calculators available for this purpose.

Once the appropriate ring and pinion have been chosen, the transmission and transmission ratios can be selected to establish an ideal Starting Line Ratio (SLR) for the combination. It is important to adjust the transmission ratio accordingly in order to tune the SLR from the beginning of the build, if optimum drag racing performance is the goal.

For example, let’s take a hypothetical combination with a goal of 150 MPH at the finish line, an RPM ceiling of 8,000, a tire height of 28 inches, and a high gear ratio of 1.00:1. With varying torque converter slip percentages, the mathematically ideal final drive ratios for this combination range from 4.399:1 to 3.863:1.

It is worth noting that the math for selecting the final drive ratio applies to all types of engines, whether naturally aspirated, nitrous assisted, supercharged, or turbocharged. It is a common misconception that turbo cars do not use 4.30 gears, as this decision is often based on misinformation or simply choosing a ratio that “sounds” right.

In some cases, the available stock ratios for a transmission may not be suitable for the desired outcome. In these situations, it is important not to compromise the final drive ratio in order to manage the SLR, as this will sacrifice the maximum performance potential of the combination. A custom torque converter will not be able to compensate for a deficiency in the final drive ratio. If a vehicle is experiencing excessive torque converter slippage, the first step in diagnosing the issue should be to examine the ratio selections in the transmission and axle.

In order to achieve the best results and reach your goals with a high-performance drag racing vehicle, it is important to take a systems approach and avoid compromising in areas such as budget and parts selection. Proper tuning from front to rear will also play a crucial role in achieving optimal results.